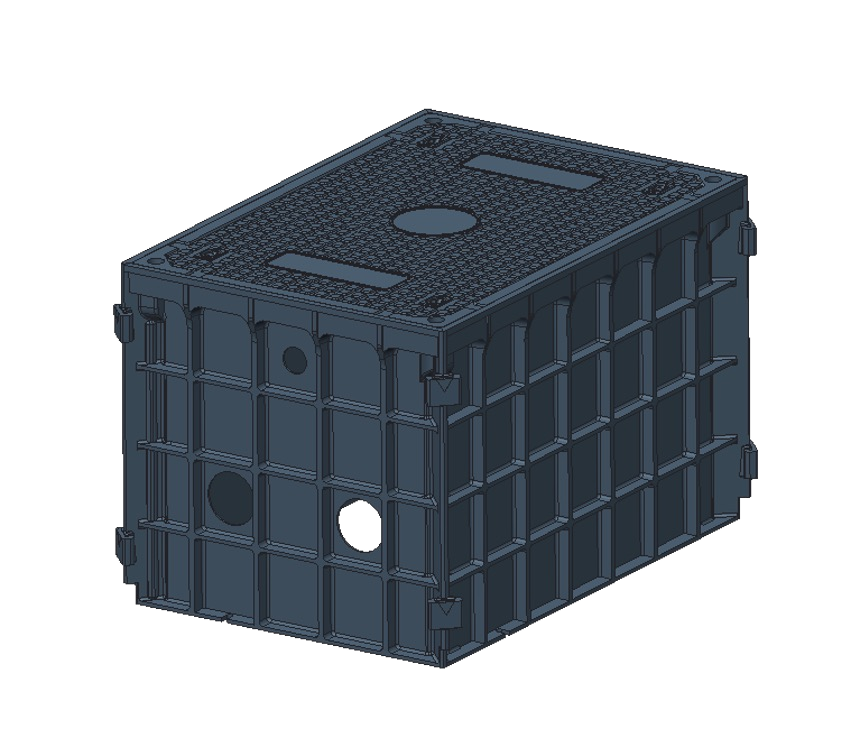

FRP Solutions

Comparison with Concrete Man / Handhole

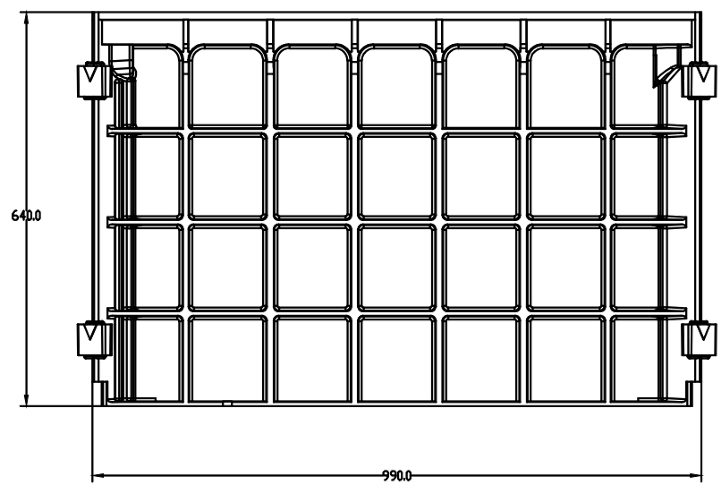

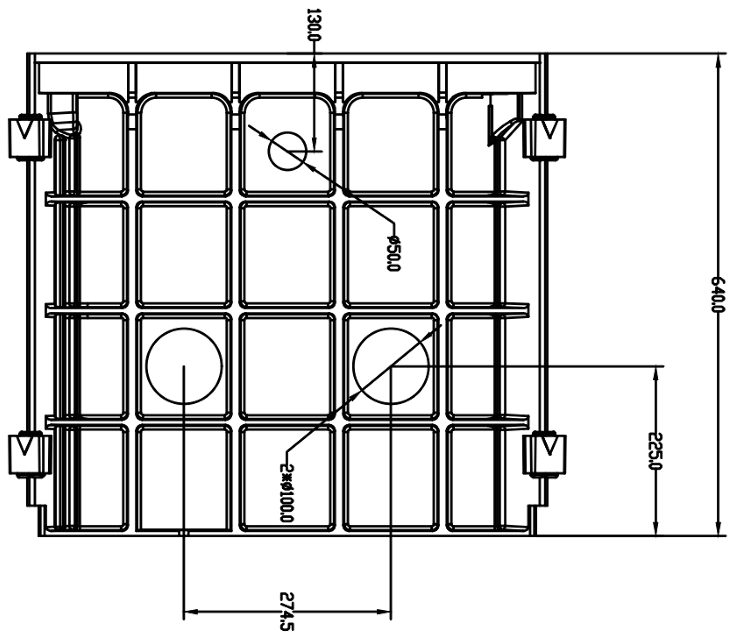

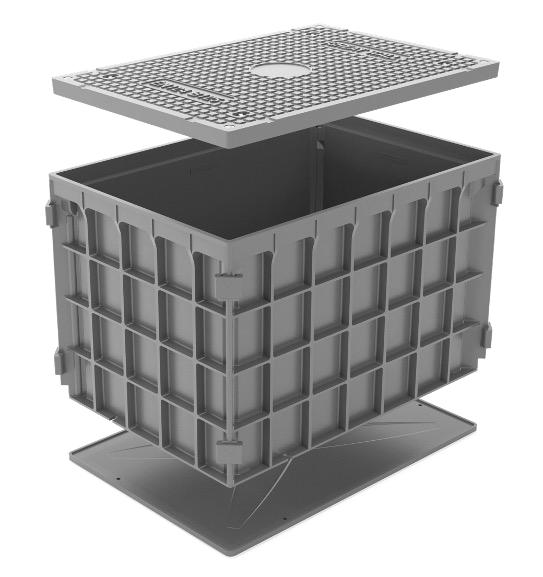

GW46(600x900x600) VS JRC7 (610x900x700)

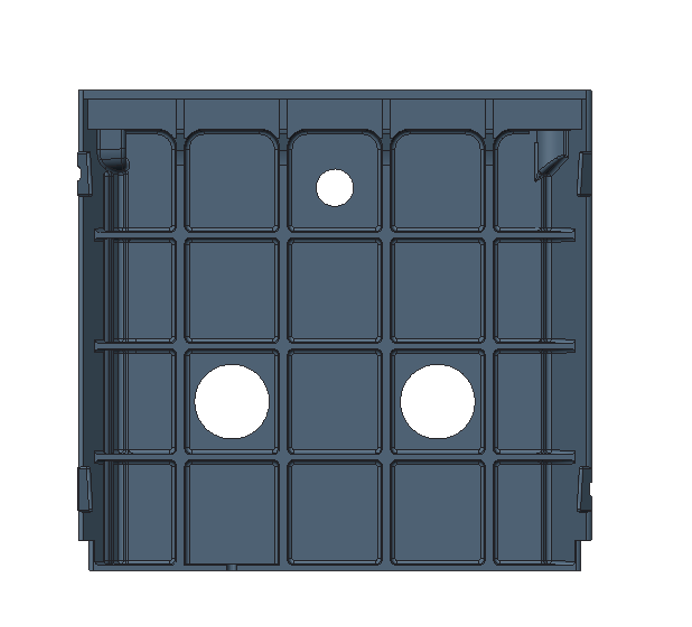

Duct holes drilled perdrawing of JRC7.

- Brand mark customizable.

- Bottom plate available.

| GW46 | JRC7 | |

|---|---|---|

| Material | SMC | Concrete |

| Internal Size | 600x900x600 | 610x900x700 |

| External Size | 690x1050x600 | 870x1160x1020 |

| Weight | 78.5kg/98.5kg | 1410kg |

| Load Capacity | EN124-B125/D400 | / |

Test Report And Certification